The compact dry ice pelletizer

The ASCO Dry Ice Pelletizer A30P is ideal for end users who wish to establish their own

in-house dry ice production.

It has a production capacity of 30 kg/h (66,14 lb/h).

To the A30P

The compact dry ice pelletizer

The ASCO Dry Ice Pelletizer A55P is ideal for end users or for gas companies to build

smaller production centres.

It has a production capacity of 55 kg/h (121.25 lb/h).

To the A55P

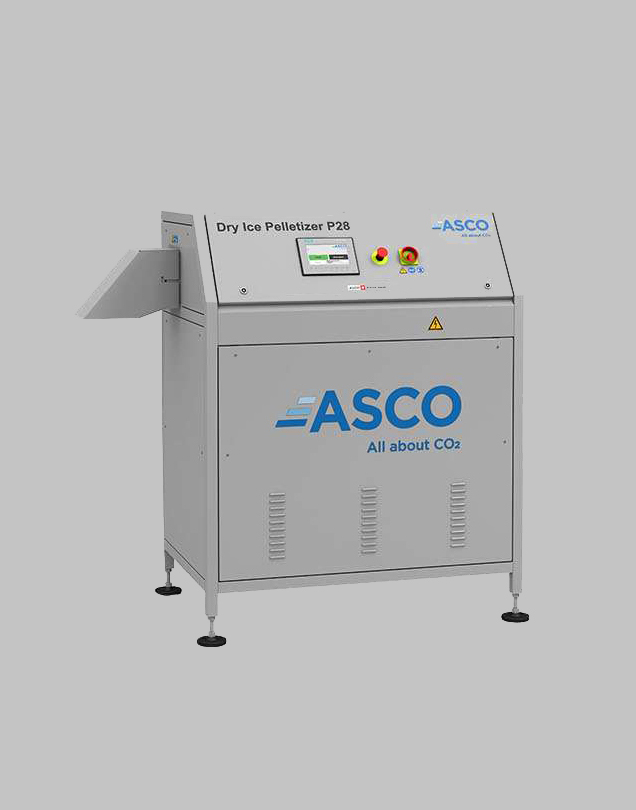

Ideal tool for gas companies

Having a production capacity of 280 kg/h (617,29 lb/h) it meets the demands for higher

dry ice quantities plus quality and flexibility in the daily working process.

To the P28i

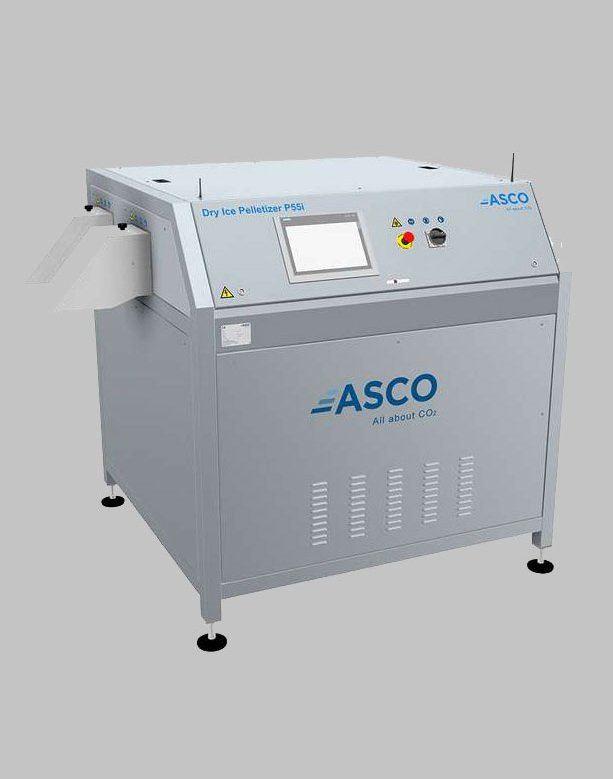

Ideal tool for gas companies

The ASCO P55i Dry Ice Pelletizer is a compact and powerful pelletizer from the i-Series

line. It produces two equal or different pellet sizes simultaneously.

To the P55i

High-capacity pelletizer

ASCO‘s most powerful pelletizer of the new i-Series. It has a production capacity of 750

kg/h (1653,47 lb/h).

To the P75i

Compact powerful pelletizer

The ASCO Dry Ice Pelletizer P15I is a compact, powerful universal machine.

It produces dry ice pellets in three different sizes and has a capacity of 150 kg/h

(330.7 lb/h).

To the P15i

Automatic pelletizer

The BP420i has a capacity from 240 to 400 kg/h (529 to 881.85 lb/h) and produces slices

in 10 different thicknesses and 2 different types of pellets.

To the BP420i

Atomatic pelletizer

The ASCO BP425i has a capacity from 190 to 400 kg/h (418 to 882 lb/h) and produces ten

different block thicknesses and two different pellet sizes at the push of a button.

To the BP425i